Is a Deep-Fried Turkey your Destiny [Photo Credit: Jinx!]

While you may think the most dangerous thing you can do during the holidays is talk politics with your uncle, starting a kitchen fire is a more realistic threat to your safety. According to the United States Fire Administration (USFA), the number of structure fires double on Thanksgiving, causing on average $28 million in property damage1. Cooking causes the majority of these blazes, with grease and oil as the main culprits in ignition2. Despite the astonishingly large number of holiday mishaps, home cooks continue using fats. A select few even engage in one of the most daring of food adventures: deep-frying a turkey.

A quick Internet search for “deep-fried turkey” reveals how dangerous this culinary practice can be. There are plenty of videos and pictures that document the aftermath of a deep-fried turkey fire. A careless and unprepared chef can turn a deep-fried turkey into a deep-fried disaster within minutes. The bird quickly becomes engulfed in a fireball that can be seen from the rest of the neighborhood. So then, what makes deep-frying more appealing than roasting? More importantly, can it be done safely?

The key to effectively deep-frying a turkey is oil. Oil makes the bird both delicious and dangerous. Oil’s interaction with the poultry causes the characteristic crispy golden brown crust that draws people to deep-frying. This same oil, however, can ignite and cause a fire. To effectively and safely deep-fry a turkey, you must understand the science underlying deep-frying.

Oil is the key to a Deep-Fried Turkey [photo credit: Joe]

The main appeal of a deep-fried turkey is the texture created by oil interacting with the bird’s skin. In deep-frying, hot oil completely engulfs the food. Put an uncooked turkey in hot oil and bubbles immediately start forming. The bubbles are not from the oil, but from the water within the surface of the bird that escapes as tiny pockets of steam. Water boils at 212 °F, but the temperature of oil in a deep fryer is typically around 350 °F or greater. Because of these high temperatures, the water in the turkey skin rapidly evaporates. This dehydration at the surface combined with the high temperature make conditions perfect for the Maillard reaction.

Maillard reactions create the characteristic deep browning and appealing aromas that you may have experienced when you deep-fry a turkey. These reactions typically occur when proteins and sugars in foods are exposed to high heat (284 – 329 °F): the amino acid building blocks of proteins react with sugars at high heat to create a complex set of flavor molecules. This is why a deep-fried turkey may evoke similar flavors and aromas as seared steak, roasted coffee, or toasted bread. As heat continues to vaporize the water on the bird’s skin, the reaction speeds up and the resulting flavor molecules become more and more concentrated.

While Maillard reactions can also be achieved through roasting a turkey, deep-frying avoids some of the pitfalls of oven roasting. First, because the hot oil completely envelops the bird, the outside gets an even brown coat. The temperature of the oil remains relatively constant as it spreads into every crevice. Such uniformity can be harder to achieve in traditional oven roasting, because of differences in air temperature within the oven. Moreover, poor heat circulation can result in uneven cooking. In extreme cases, you might find one side of the turkey charred, while the other is still undercooked.

Next, because the oil can transfer more heat than air per unit volume and time, deep-frying can allow the bird’s surface to get hot quickly enough so that the inside does not overcook. In deep-frying, oil acts as the workhorse transferring heat to food. By contrast, ovens rely on air to transfer heat. Compared to air, cooking oil has a much higher rate of heat conduction. Heat transfers between substances when the molecules collide and transfer energy. Because a liquid such as oil is more dense then air, its molecules are more closely packed; there are more molecules per volume to transfer energy. As a result, the high heat needed for the Maillard reactions develops much faster in a deep fryer than in the oven. In general, oven roasting generally takes about 2-4 hours, while deep-frying can take as little as 30 minutes. Slower increases in surface temperature, as in the case of the oven, allow for more time for the high heat to spread to the center of the turkey and overcook the inside.

Many deep-frying fans claim that the practice “seals in the juices”, however, internal temperature has a larger impact on moisture. If you’ve ever bit into a dry piece of fried chicken, you know, that deep-frying does not guarantee juicy poultry. Fans claim that oil creates a barrier to lock in moisture, but as previously highlighted, hot oil causes it to vaporize and escape. Even water near the interior can escape if it reaches the boiling point because the crust remains porous. The meat on the inside cooks in the same way as in roasting, but only faster because the oil transfers more heat. Thus, regardless of whether you deep-fry or roast the bird, you need to watch the internal temperature to get a juicy turkey.

While hot oil is essential for transforming your turkey into a delicious brown and crispy treat, properly controlling the oil will keep you safe. The first step is having the proper equipment. While a turkey can be deep fried in any number of large pots you already have, none of them are specifically designed to safely handle 3 gallons or more of hot oil and a giant turkey. Having a deep fryer specific for turkeys ensures that when you use the right amount of oil, the turkey is completely submerged and the oil won’t overflow. Also you can cook with a turkey deep fryer outside; this keeps the hot oil safely away from anything flammable in your home. So if you do make a mistake, it’s far away from anything that can spread a fire.

Next, to avoid turning the turkey into a giant fireball, it must be properly dried. This means checking that the bird is completely thawed and free of excess water. If too much ice or water remain, either can quickly vaporize causing oil to spray into the air. You may have seen a similar reaction occur when you throw drops of water into hot oil to test if it’s reached frying temperature. Sudden vaporization results in tiny droplets of oil spewing out in a fine mist. As microscopic droplets, the oil increases its chances of contacting the burner and reaching its flash point, or the temperature at which a material can ignite. (The flash point is around 600-700°F for many cooking oils.) In the deep fryer, oil won’t get as hot, but as droplets, oil can reach this temperature because of their small size and increased surface area. The ignition of a few small oil droplets can set off a chain reaction that engulfs the entire bird. This is why a seemingly innocent icy turkey can turn into a fireball.

Finally, you may want to consider that deep-frying adds a significant amount of fat to your bird compared to roasting it. The entire surface of the turkey is covered in oil and some may seep into the interior. In general, deep-frying can result in as much as 5 to 40% of a food’s weight in oil3. If you are concerned about your fat intake you might want to avoid this deep-fried treat. However, eating a deep-fried bird only on Thanksgiving likely won’t jeopardize your health too much.

Deep-frying a turkey requires significant culinary effort. Although this cooking method is potentially dangerous, your fowl can develop delicious flavors and aromas that cannot be achieved as quickly in the oven. Whether or not you want to make the investment ultimately depends on what you like about eating turkey. If you only care about juicy meat, then using an oven and monitoring the temperature can be easier. However, if you crave a truly unique treat encased in a crispy brown crust, then deep-frying a turkey may be your next gastronomic adventure.

References cited

- USFA. Thanksgiving Day Fires in Residential Buildings (2009-2011) http://www.usfa.fema.gov/downloads/pdf/statistics/snapshot_thanksgiving.pdf

- USFA. Cooking Fires in Residential Buildings (2008-2010) http://www.usfa.fema.gov/downloads/pdf/statistics/v13i12.pdf

- Owen R. Fennema, editor, Food Chemistry, 2nd Edition (New York: Marcel Dekker, Inc, 1985), 210-221

About the author: Vince Reyes earned his Ph.D. in Civil Engineering at UCLA. Vince loves to explore the deliciousness of all things edible.

About the author: Vince Reyes earned his Ph.D. in Civil Engineering at UCLA. Vince loves to explore the deliciousness of all things edible.

Read more by Vince Reyes

About the author: Ashton Yoon received her B.S. in Environmental Science at UCLA and is currently pursuing a graduate degree in food science. Her favorite pastime is experimenting in the kitchen with new recipes and cooking techniques.

About the author: Ashton Yoon received her B.S. in Environmental Science at UCLA and is currently pursuing a graduate degree in food science. Her favorite pastime is experimenting in the kitchen with new recipes and cooking techniques.

![[Photo Credit: Vince C Reyes]](https://scienceandfooducla.files.wordpress.com/2015/01/img_0812.jpg?w=660)

![Figure 1: Molecular Formula of Ethanol [Image Credit: Vince C Reyes]](https://scienceandfooducla.files.wordpress.com/2015/01/ethanol.jpg?w=660)

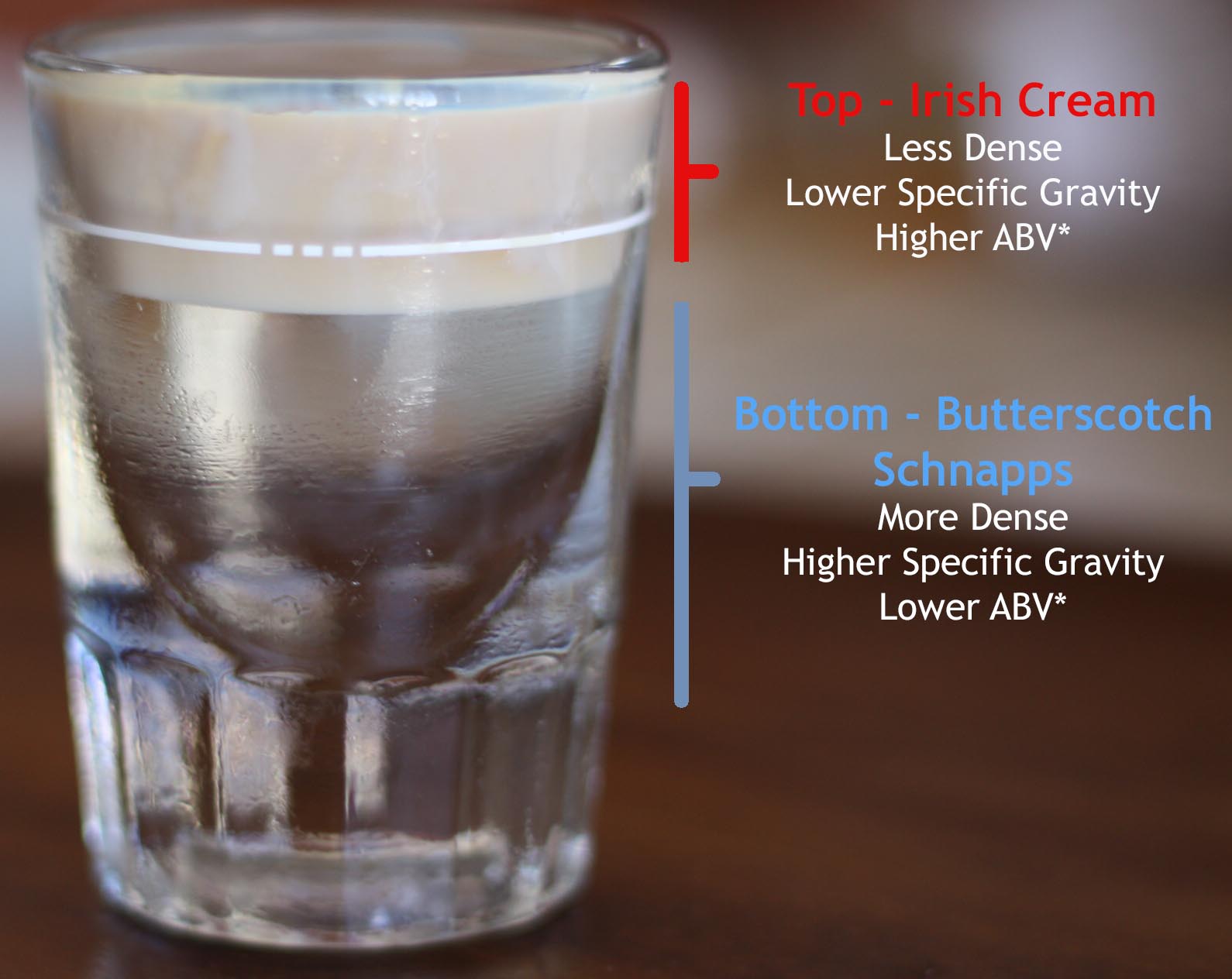

![Figure 2: Layering in a Buttery Nipple. *ABV is not always an indicator of density. [Image Credit: Vince C Reyes]](https://scienceandfooducla.files.wordpress.com/2015/01/diagram.jpg?w=660)